Milking Stool

(Finished 01/12/2025)

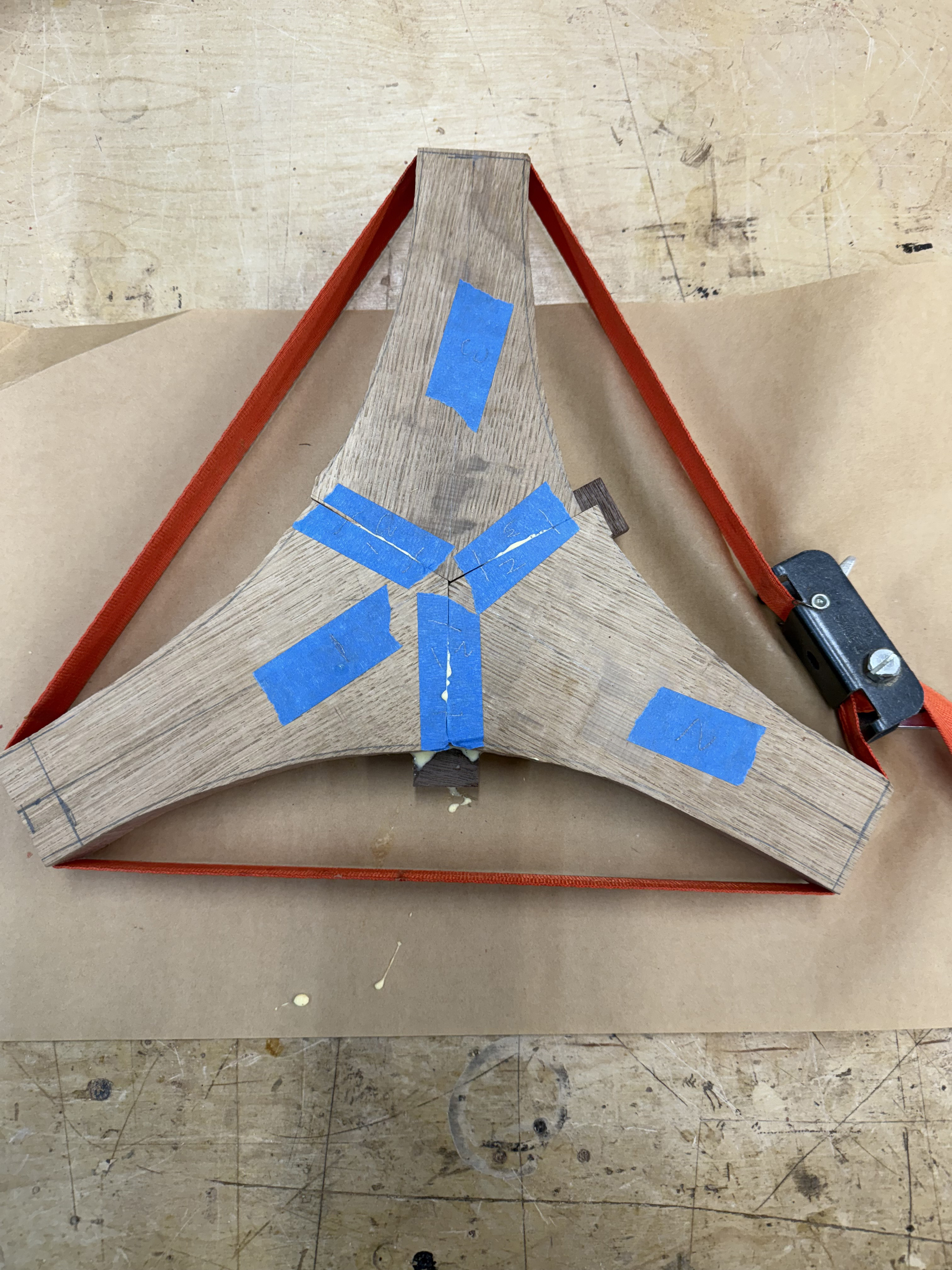

When we were first married we took a trip to visit a friend in Indiana. While there, we visited several antique markets. We found a very unique antique Milking Stool. So, we bought it and brought it back home with us. 50 years later I decided to make a replica of the Milking Stool, using the same joinery and many of the same antique woodworking methods. |

|---|

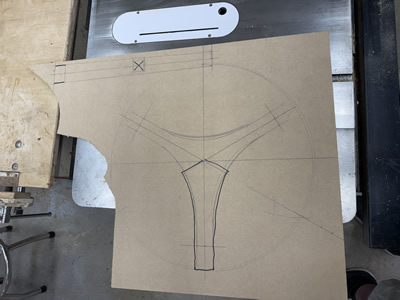

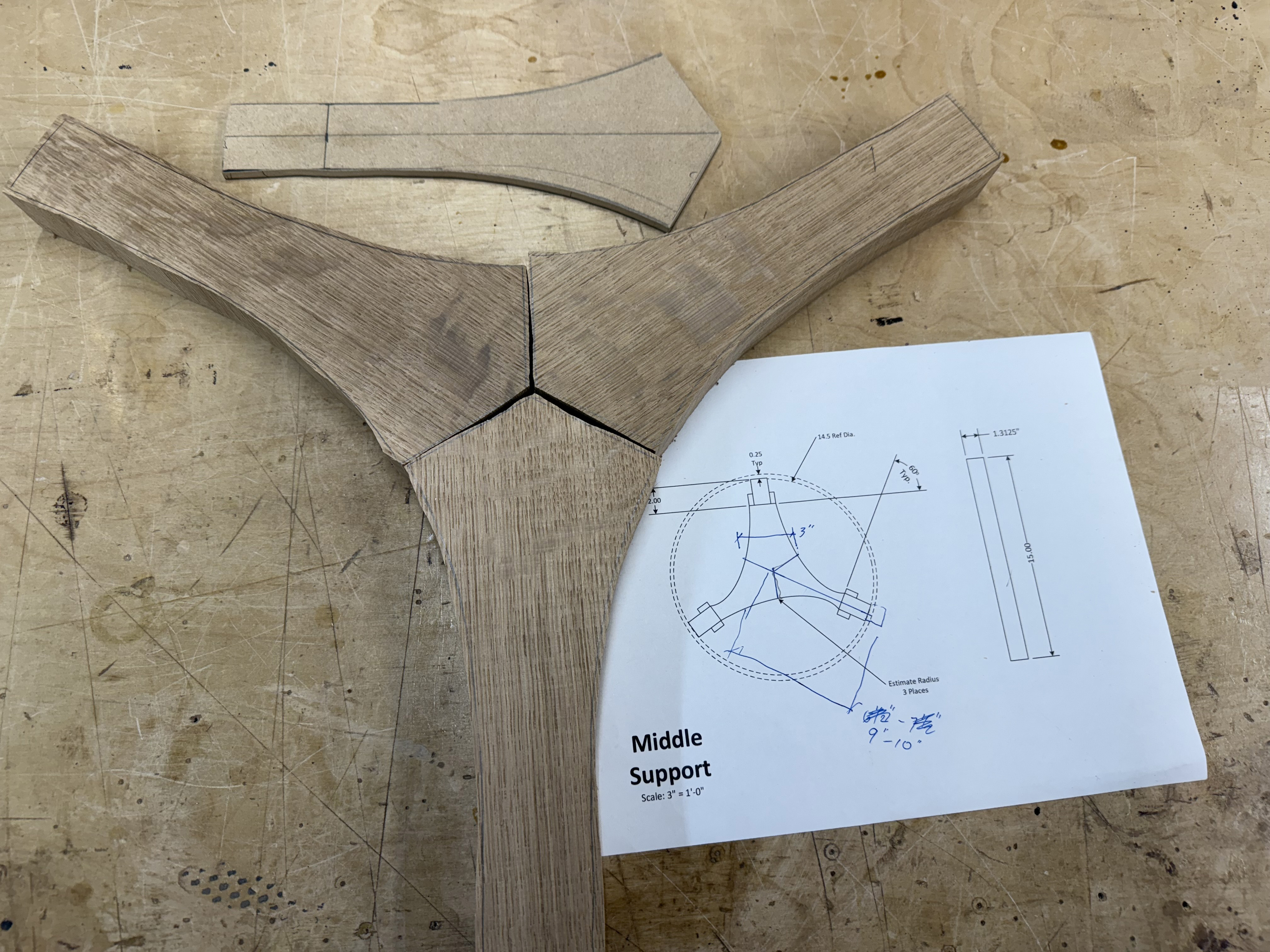

Drawing of Milking Stool - Make a drawing of the componenets first.

I am very happy with the finished Milking Stool. While you can tell the difference between teh orginal and the copy, they do look very similiar. The most fun was making the virtually the same way as they did in the late 1800's. Fun Project. |

||||||||||||||||||